Oil Green Dyes

Product Details:

- Purity >99

- Grade Industrial Grade

- Type Solvent Dye

- EINECS No 201-417-2

- Physical Form Liquid

- Click to View more

Oil Green Dyes Price And Quantity

- 300 INR/Kilograms

- 100 Kilograms

Oil Green Dyes Product Specifications

- Industrial Grade

- Solvent Dye

- Liquid

- >99

- 201-417-2

Oil Green Dyes Trade Information

- 3 Kilograms Per Week

- 3 Week

Product Description

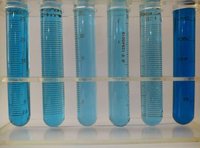

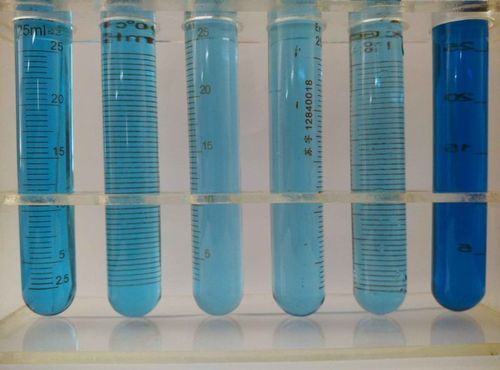

Oil Green Dyes we deal in are useful for coloring the organic solvents, waxes, lubricants, hydrocarbon fuels, hydrocarbon-based non-polar materials and plastics. These are suited for coloring a wide variety of solid materials, such as acetates, PVC, acrylics, PMMA, nylon, polyester, polystyrene, styrene monomers and PETP. These solvent soluble dyes have extensive use in inks as well as coating industries. Oil Green Dyes are functional as the advanced solutions in the organic solvent. They are accessible with better-quality solubility and are useful for several applications.

Specification

|

Chemical description |

Anthraquinone |

|

Transparent |

0.05% |

|

Shade |

Bluish green |

|

Reduction |

0.20% |

|

Migration Resistance |

4-5 |

|

Light Fastness |

7-8 |

Highly Pure Industrial Dye

Our Oil Green Dyes boast a purity of over 99%, making them especially suitable for demanding industrial applications. This high standard ensures vivid, consistent coloration in every use, supported by our stringent manufacturing processes and quality control measures in India.

Versatile Solvent-Based Solution

Offered in liquid form, Oil Green Dyes integrate seamlessly with oil-based products and processes. They dissolve quickly and evenly, providing uniform color distribution in plastics, fuels, and lubricants, contributing to both visual appeal and functional marking.

FAQs of Oil Green Dyes:

Q: How should Oil Green Dyes be used in industrial applications?

A: Oil Green Dyes are typically added directly to oil-based systems such as plastics, lubricants, and fuels. Their liquid solvent form ensures easy mixing and homogenous color dispersion, making them suitable for continuous processing or batch mixing.Q: What are the key benefits of using Oil Green Dyes of industrial grade and high purity?

A: High purity (over 99%) ensures strong, stable coloration without contaminants that could affect product performance or appearance. Industrial grade quality supports durability, consistent results, and compliance with rigorous industry standards.Q: When is it appropriate to use Oil Green Dyes in production?

A: Oil Green Dyes should be used during the coloring stage of production processes involving plastics, oils, greases, or fuels. Their stable properties allow them to be introduced early during blending or compounding for optimal color integration.Q: Where are these Oil Green Dyes manufactured and exported from?

A: These dyes are produced and exported from India, where advanced manufacturing facilities and comprehensive quality systems ensure reliable supply and adherence to international specifications.Q: What is the process for manufacturing Oil Green Dyes with EINECS No: 201-417-2?

A: The dyes are synthesized through carefully controlled chemical reactions, producing a high-purity solvent dye. Extensive filtration and quality checks guarantee compliance with EINECS No: 201-417-2 standards.Q: What types of products can Oil Green Dyes be used in?

A: They are suitable for use in a wide array of oil-based products such as fuels, lubricants, waxes, and specific plastics, providing coloration and functional identification.Q: How does the exporter ensure the quality and timely delivery of Oil Green Dyes?

A: As an established exporter and manufacturer, we utilize robust supply chain practices and transparent communication, ensuring the dyes meet quality requirements and are delivered on time to global clients.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese